highly

sought after in China

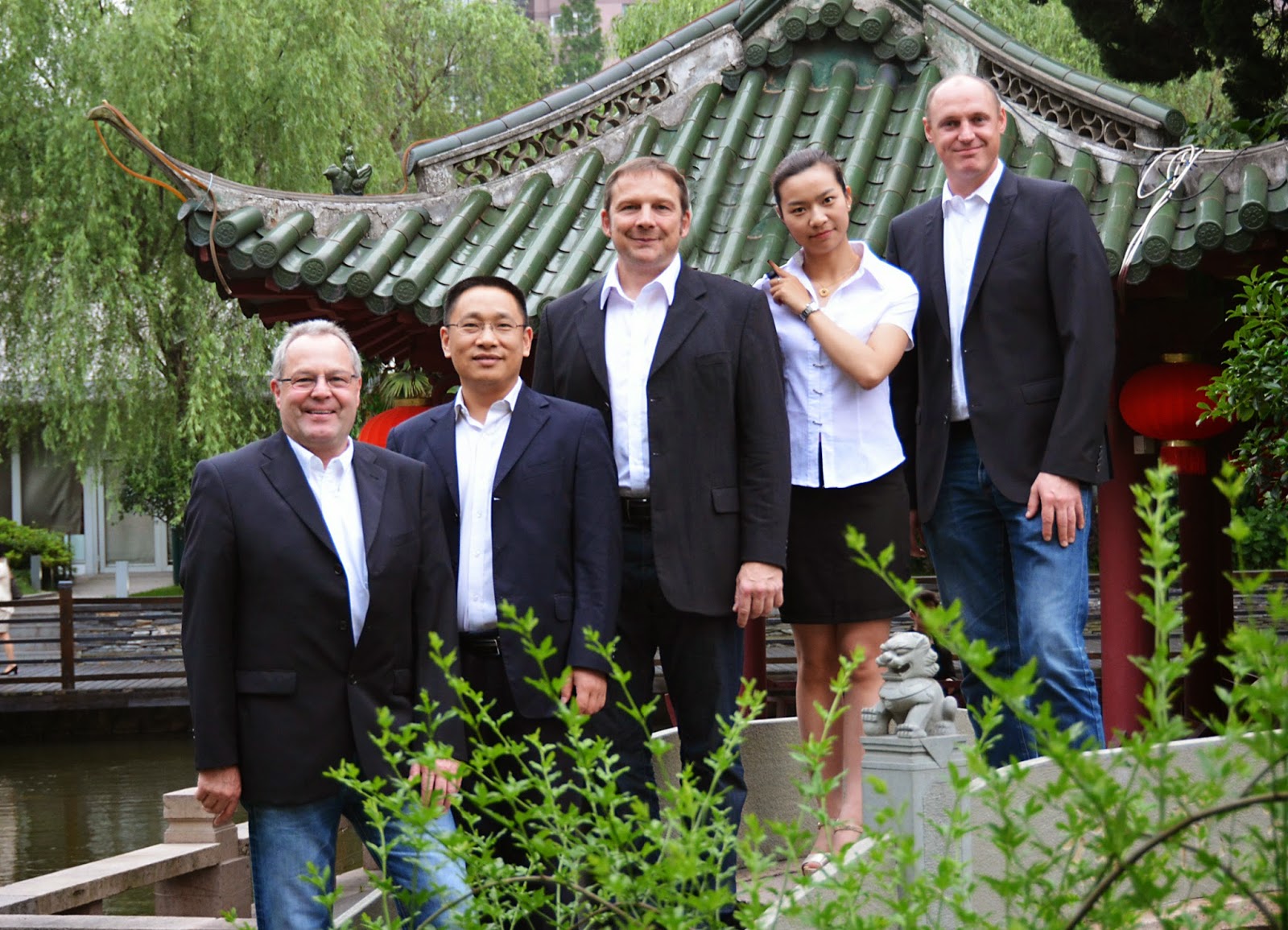

Fill Machine Engineering establishes wholly-owned

subsidiary in China. Presence in the largest automotive market in the world

generates new opportunities.

Fill

China was recently established with a head office in Shanghai. The new overseas

branch of the company will allow the Upper Austrian machine engineering

specialists to deal with the emerging Chinese market even more rigorously. Fill

machines are already being used successfully at ten locations throughout China.

With production of around 19 million vehicles (cars and commercial vehicles) per

year, China is the world´s largest market in the automotive sector. And it´s

growing rapidly. The aerospace industry is also booming in the Middle Kingdom.

Above all, quality "made by Fill" is highly sought after in China.

Gurten,

4th June 2014 –

In recent years, China has developed into one of the world´s most important

foundry markets. This is primarily due to the up-and-coming automotive industry.

Fill Machine Engineering supplies many renowned automotive manufacturers in

Europe and America with production systems for manufacturing cylinder heads and

in the field of aluminum casting. Attention has now been turned to the business

in China. "We are currently working on seven projects in China, with a total

order value of around 16 million euros. The founding of Fill China with a

five-strong sales and service team places us closer to the customer and will

allow us to further expand our position as a market and technological leader,"

explains Thomas Rathner, General Manager of Fill China and Head of the Metal

Competence Center at Fill.

Huge

potential

Rapid

growth of the Chinese market in the automotive and composite sectors is

stimulating demand for high-quality machines and systems. Above all, huge

potential for casting, cooling and raw part machining systems exists here in

aluminum and iron foundries. Demand for fiber-reinforced composites is also

rising continuously. These fields number among Fill Machine Engineering´s core

areas of expertise. The company is highly successful internationally, not only

as a machine and plant engineer, but also as a systems integrator.

Boom

in the aerospace industry

In

it´s annual "Current Market Outlook" (CMO), aircraft manufacturer Boeing

foresees a demand of around 35,000 new aircraft in the next 20 years. More than

a third of these in the Asia-Pacific region. Fill has now also achieved initial

success in this important industrial sector with an NDT ultrasound inspection

system for testing carbon structures for a factory in Nanjing. There is a great

deal of interest in further Fill machines and systems.

Corporate

data

Fill

is a leading international machine and plant manufacturing company for diverse

branches of industry. The family-owned business excels in the use of the latest

technologies in management, communication, and production. Business operations

encompass the fields of metal, plastics and wood for the automotive, aircraft,

wind energy, sport and building industries. The company is the global market

leader in ski and snowboard production machines and aluminum core removal

technology. Andreas Fill and Wolfgang Rathner are joint CEOs of the company

founded in 1966 that is still completely family-owned. The company became a

public limited company (GmbH) in 1987, was certified in accordance with ISO 9001

in 1997, and now has more than 590 employees. In 2013, the company recorded

sales of just under 115 million euros.

Further

information can be found at: www.fill.co.at

If you have any questions, please contact:

Kommhaus

Altausseer Strasse 220

8990 Bad Aussee / Austria

Tel.: +43 3622 55344-0

Fax: +43 3622 55344-17

E-mail: presse@kommhaus.com

http://www.fill.co.at/en/press/expertise-from-the-innviertel-highly-sought-after-in-china/1077i1n493.html