High-tech goes wood – Fill automates wood processing

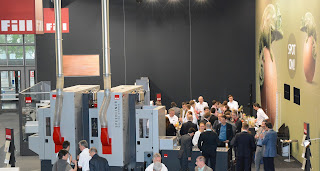

New technologies increase cost-effectiveness and raise quality. Successful presentation at the LIGNA in Hannover.

Fully automatic, high-speed retouching of plywood and solid wood boards with Fill speedfiller systems; speedliner hybrid bandsaws for perfect wet and dry cutting, plus interconnection of the processes individually tailored to customer requirements: Austrian machine engineering company Fill appeared at the woodworking industry´s leading trade fair, LIGNA, from 11 to 15 May 2015 in Hannover, with a whole range of innovations. In addition, speedfiller technology was presented as one of only 20 top innovations at the 2015 LIGNA innovation symposium. Furthermore, Fill is happy to have received a large order from a renowned Swiss timber construction company.

Hannover/Gurten, 26 May 2015 – "Fill your future" – following this creed in the company´s guiding principles, Fill presented pioneering technologies at LIGNA, the world´s leading trade fair for the forestry and wood industries, from 11 to 15 May. "In the wood processing industry, there are definitely still areas in need of further technical development. From automation through to industrial production, huge potential exists with regard to cost-effectiveness and quality. This can generate a real competitive advantage," explains Erwin Altendorfer, Manager of the Wood Competence Center at Fill. A renowned Swiss timber construction company is so convinced of this that it placed a major automation order at the trade fair with the Innviertel-based machine engineering experts.

Woodworking of the future

The Fill speedfiller is currently the highest-performance system available on the market for retouching plywood and solid wood boards. Surface flaws are repaired completely automatically, reproducibly, and with consistent quality. Flexible configurations allow systems to be adapted individually to customer requirements in each case. In recognition of this, speedfiller technology from Fill was presented as one of the trade fair´s outstanding innovations at the 2015 LIGNA innovation symposium. The speedliner hybrid bandsaws perfect the wet and dry cutting of solid wood. The benefits of being able to cut wet raw materials are obvious: It shortens the time spent in the drying chamber substantially, energy and materials are saved, and less capital is tied up.

Corporate data

Fill is a leading international machine and plant manufacturing company serving diverse branches of industry. The family-owned business excels in the use of the latest technology and methods in management, communication, and production. Business operations encompass the fields of metal, plastics and wood for the automotive, aircraft, wind energy, sport and building industries. The company is the global market leader in aluminum core removal technology, casting technology, as well as in ski and snowboard production machines. Andreas Fill and Wolfgang Rathner are joint CEOs of the company founded in 1966 that is still completely family-owned and now has more than 640 employees. In 2014, the company recorded sales of 120 million euros.

Further information can be found at: www.fill.co.at

If you have any questions, please contact:

Kommhaus

Altausseer Strasse 220

8990 Bad Aussee / Austria

Tel.: +43 3622 55344-0

Fax: +43 3622 55344-17

E-mail: presse@kommhaus.com

http://www.fill.co.at/en/press/high-tech-goes-wood-fill-automates-wood-processing/1077i1n550.html

Keine Kommentare:

Kommentar veröffentlichen